Combined and effective

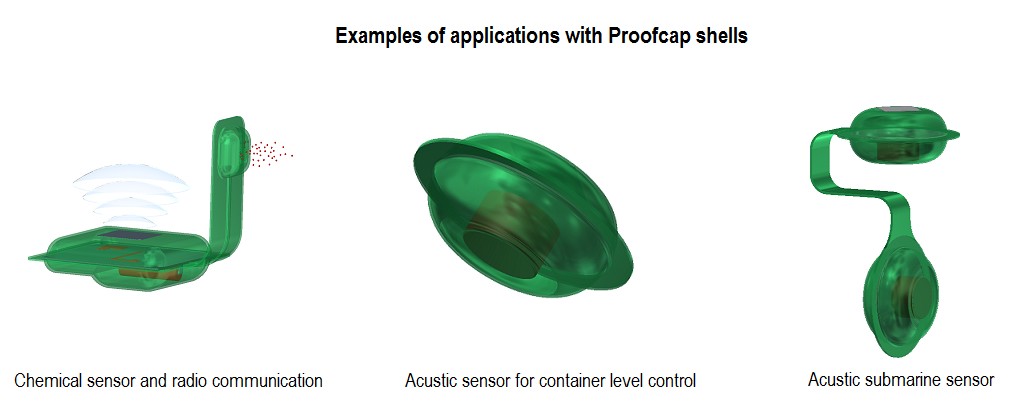

The ProofCap technique combines excellent shielding and protection properties with environmentally friendly materials and a simple production process. ProofCap allows for new and flexible designs with short lead-time. This means optimised and cost effective solutions.

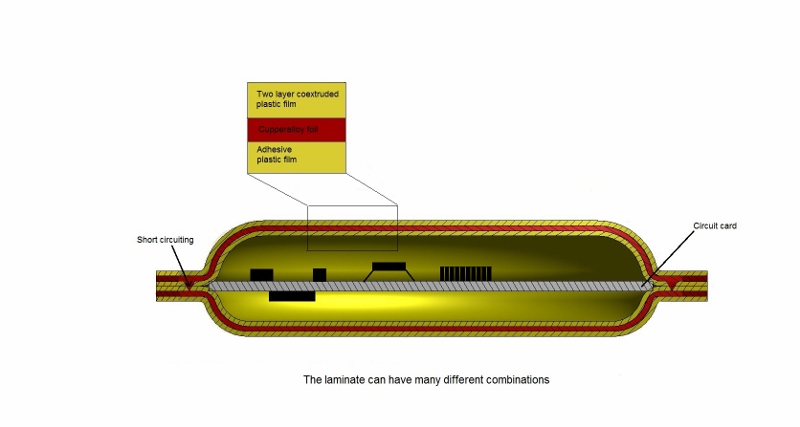

The ProofCap laminate consists of metal foils and plastic films. The laminate is formed in a press to fit the electronic board and the components. An outer stainless steel foil or plastic film provides corrosion and fire protection as well having an attractive surface for marking and logos. The inner cupper alloy foil can be grounded to the electronic to provide effective shielding. The plastic films provide electrical insulation and allow for melt-sealing of the ProofCap cover to the electronic board. Metal foils blocks out humidity and function as shielding of the electronics.The sealing film has a very good adhesion and it is constant in severe humidity and long time.Patchantennas can be integrated in the ProofCap-shell. Such applications is handled together with our co work company GlobalSense AB and Dr. Urban Lundgren.ProofCap-shells and equipment for sealing has

protect circuits in fish breading industry and radio transmitters for building cranes for more than 12 years, in very harsh environment.The materials and methods are continously developed to a very high standard.

ERICSSON Micro base station

Outdoor air is used as coolant in this project with the objective to create a more compact, low weight and effective Micro Base Station. ProofCap fulfills all set requirements and has resulted in a low weight, repairable and environmental friendly product. 65 dB dampening was possible to achieve for 800-900 MHz.