Simple and effective

Effective shielding solutions are possible to achieve with ProofCap laminate. Up to 60 dB dampening, or more, has been measured for telecom applications. The ProofCap cover is connected to the PCB with short-circuiting strips and cavities are easily formed to separate functions and sectors of the PCB.

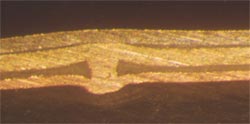

The cross section photo shows how the short-circuiting strip connects the ProofCap cover with the PCB. The 2 upper metal surfaces are part of the ProofCap laminate. The bottom metal surface is the copper traces on the PCB. Note that the electrical contact between the ProofCap cover and PCB by the short circuiting strip is protected by melted plastic film.

The electrical contact between ProofCap cover and PCB as well metal surfaces are all well protected by the melted inner plastic film. This results in long term effective shielding properties. The short circuiting strip is integrated in the ProofCap cover and thus reduce the number of extra items and operations. Conductive gaskets and metal surfaces often detoriate quickly and require correct contact pressure.

ProofCap shielding saves weight when compared to casted aluminium boxes, a 100×100 mm ProofCap cover weighs typically 20 grams.