Flexible and new design options

The unique features of the ProofCap laminate creates new design possibilities. Simple tooling with short lead-time makes ProofCap ideal for fast prototyping, which results in optimised and competitive products.

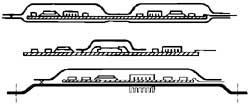

ProofCap can be used to fully encase an electronic board or to create separate shielding areas. The flexibility yet good adhesion strength of ProofCap ensures that semi-rigid conductors can easily be created and mechanical items such as cooler, front and fixing items integrated. Thicker ProofCap laminate can be chosen to function as fixation and cooling. For permanent outdoor use it is necessary to completly enclose the circuitcard all around.

Soldering pads, electrical conductors and antenna patterns can be applied directly onto the ProofCap laminate to facilitate new, integrated and low weight solutions. The ProofCap cover can replace an outer protection and designed cover. Company and product logos are easily integrated in the ProofCap forming tool, printed, painted or by using labels.

There is only need for a single sided tool for the cold forming of the ProofCap cover. Lead time and tooling cost are both significantly reduced. This means optimal project flexibility and cost effective solutions for low volume applications.